Small Piece Folding Technology

The need for dry folding of small pieces occurs in almost every laundry around the world. There are three basic concepts to tumble dry small parts; manual hand folding, machine folding, or bagging. Each process is as simple as it sounds, but with many different solutions it can be confusing to determine what concept is correct. The end customer’s requirements for quality folded parts, size, and presentation will always establish what process best supports their needs. Hand folding is just that, a slow, labor-intensive process typically used in clean rooms or by exception for a small amount of goods. Bagging is often used in industrial laundries processing large volumes of shop rags or towels where folding is not required. This is a very quick and efficient process.

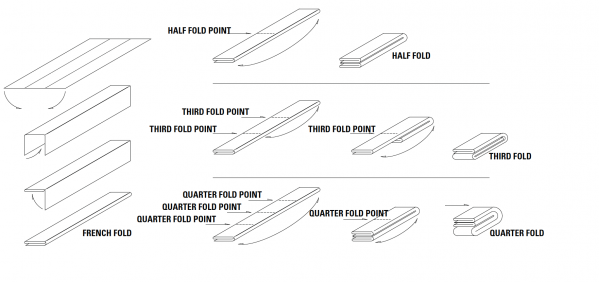

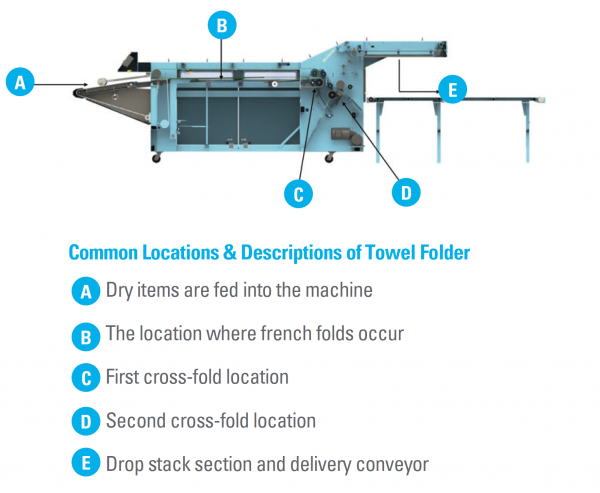

Most small piece folders manufactured today are capable of folding various widths, weights, and types of goods with French fold and two cross folds. Other, more specific engineered equipment, is also available in the market for point solutions and is limited to the specific type of item for which they were designed.

Common Configurations of Towel Folding

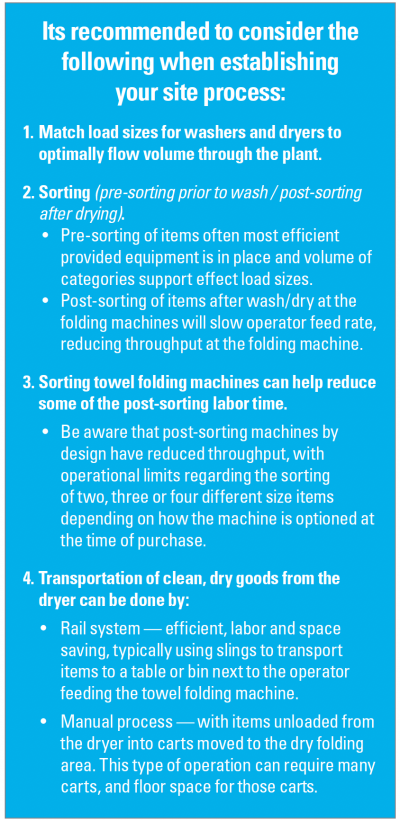

Depending on the capabilities of the laundry and the volume/mix of products to be folded, some sites may elect to presort into categories (i.e. customer’s goods, terry bath towels/mats, pool towels, other than terry products), optimizing the process at the folding machines.

It is important for items to be fully dry before folding them. This especially applies to the hems prior to processing in the folder, or there may be restrictions or jams in machines causing damage to the machine and the product processed. This dry condition also applies to parts like shop rags that are typically being bagged by weight and to avoid the development of bacterial growth or odors.

With respect to the machine folding process, a laundry worker places an item to be folded onto the infeed of the folding machine. Depending on type of folder being used, activation of the infeed conveyor might require the operator to make a second motion activating an input to put the infeed conveyor in motion to start the fold process. Some machine designs support continuous infeed operation, those designs require no user interface other than placing the item onto the infeed conveyor already in motion. As the fed item enters the machine it will be measured, then folded to the desired pre-selected, pre-programed fold configuration, then stacked. Stacks are built in multiples of 5 with varying heights depending on the size of folded part. Commonly, once items are folded the stacks are placed in clean goods carts for delivery to the end users. These carts may or may not be lined with cart liners depending on the user’s requirements. Some end users may require that goods be bundled, wrapped and bagged in stacks of a specific number. Several different delivery methods for transporting stack folded items from the folding machine to carts or pack-out exist. The configuration of purchased dry folding equipment (return to feed, rear discharge or sorting machine) will define this process, methods, or options available to transport folded stacks.

With respect to the machine folding process, a laundry worker places an item to be folded onto the infeed of the folding machine. Depending on type of folder being used, activation of the infeed conveyor might require the operator to make a second motion activating an input to put the infeed conveyor in motion to start the fold process. Some machine designs support continuous infeed operation, those designs require no user interface other than placing the item onto the infeed conveyor already in motion. As the fed item enters the machine it will be measured, then folded to the desired pre-selected, pre-programed fold configuration, then stacked. Stacks are built in multiples of 5 with varying heights depending on the size of folded part. Commonly, once items are folded the stacks are placed in clean goods carts for delivery to the end users. These carts may or may not be lined with cart liners depending on the user’s requirements. Some end users may require that goods be bundled, wrapped and bagged in stacks of a specific number. Several different delivery methods for transporting stack folded items from the folding machine to carts or pack-out exist. The configuration of purchased dry folding equipment (return to feed, rear discharge or sorting machine) will define this process, methods, or options available to transport folded stacks.

Markets Served and Relationship to Tumble Dry Small Piece Folding

Manual processing (hand folding) typically uses a large table with multiple personnel folding goods from piles of clean goods (on a table or in a cart) and stacking them in delivery carts. One person can typically fold and stack 120-200 pieces per hour. Most often found in clean room processing, this type of operation is end user specific. It usually involves hand folding and individually bagging and sealing goods for use in operating rooms or other similar environments. Laundries will have dedicated space for processing these goods and requirements for sterile hygiene and apparel to be worn when working in those environments. The advantage of a manual, dry folding process is that personnel can perform the final quality inspection, and in some cases delint each item as they are folding it. Also, fold quality can be higher as the fold is completed by a human that is constantly correcting and straightening each individual fold during the fold process. Aside from being a labor-intensive process, production rates of one person hand folding goods versus one person feeding a folding machine is not comparable; provided services should be costed accordingly.

Semi-Automated processing or bagging systems are typically found in industrial laundries producing a high volume of small parts (e.g. shop rags or shop towels). The end user requirement for these items is simple; parts need to be clean/dry, and presentation is not a concern. With this process, goods are vacuumed and bagged by weight and delivered to the end user in a bag, reducing labor handling costs. It is important that all items must be completely dry to prevent bacterial growth or development of odor while stored in the bags. Also, operators must consider the cost of consumable bags when totally evaluating this cost and the associated ROI for using this method.

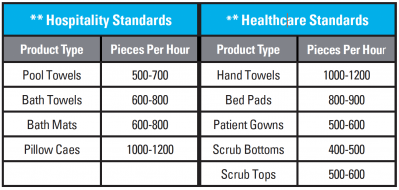

** Standards are based on full dry common sized items. Your piece rate will vary based on internal process, equipment used and product type. Recommened to review your actual tested metrics to this chart.

Folding with a machine works best when items are prestaged in either load slings or laundry bins. Machine operators remove individual goods from the bins and place them on the infeed table of the folder. Parts discharge onto a conveyor in a stack and an operator removes the stack by hand. The stack may be bagged or tied prior to being placed in a clean laundry bin for delivery to the end user. A small piece folding machine operator can feed between 500-1,000 pieces per hour depending on goods type and operator skill level. Another configuration of the same base folding machine is to have all folded/stacked goods discharged onto a take away conveyor. This discharge, when used with a takeaway conveyor, expands the options for tying and wrapping machines. This solution option results in a reduction of material and direct labor, while improving productivity.

Small Piece Folding Machine Configurations and Features

Three most common machine folder configurations are return-to-feed, rear discharge, and sorting by size machines. Equipment manufacturers will keep the base machine infeed, user interface and folding configurations the same with each of the noted configurations. Only changing the discharge or stacking sections to support the item’s needs for movement in the proper direction after folding is completed. Sorting machines will often be longer in length to accommodate various-sized sorting takeaway conveyors. Differences with equipment designs may require machine infeed tables to start/stop with each part. Some will run continuously, while others will pause depending on width changes to the items being folded. Some vendor’s machines have restrictive product ranges, which limit the flexibility of the machine. It is vital that the mix of goods processed best aligns with the machines range of capabilities. This reduces capital equipment cost, improves space utilization, and optimizes the use of available labor.

Return-to-feed machines can have a smaller machine footprint for laundries that have limited floor space. Operators that feed the machine are also removing the folded piece from the stack conveyor and placing the stacked goods in the delivery bin for the end user. This process may have a detrimental effect on machine throughput, as the operator is performing multiple tasks. Items must be sorted by type prior to being fed into this machine. Sorting can occur before or after the wash/dry process.

Rear discharge machines have a potentially higher production throughput, as the operator feeding the machine is not required to multitask and is only concerned with feeding the machine. Folded and stacked goods are taken away from the machine and can automatically go onto a clean goods conveyor, if available. Some machines may have a larger footprint as the takeaway conveyor is external to the machine. Depending on the equipment design, this takeaway conveyor might be in-line with the machine for a narrow footprint, or extend out either side, increasing base machine width. Items must be sorted by type prior to being fed into this machine. Sorting can occur before or after the wash/dry process.

Sorting machines allow for all parts, regardless of size, to be processed concurrently. The process of measuring for size may have a detrimental effect on operator throughput because the machine may need extra time to measure each individual part, or delay infeed of the next item fed if it’s a different size. This sorting function will vary depending on how the machine is designed to operate.

The most common types of folders on the market make folds using compressed air, mechanical fold blades, and reversing conveyors. Most folders use 2 or more of these functions to make the complete fold.

Compressed air folders use compressed air to complete the primary and cross folds. The compressed air is blasted at the dry fold items. The item is either stationary or traveling along a guide while the activated air folds the part along that guide. This type of folder requires a high consumption of compressed air. This type of fold is dependent on air quality. There may be a decrease in fold quality if the supply of compressed air falls short of the manufacturer’s recommended pressure. If air filtering is poor and there is water or debris in the compressed air supply, it will limit the repeatability of the fold process.

Folders with mechanical blades are often used to complete the primary and cross folds. These mechanical components are clean, provide positive fold point of contact and need regular attention during equipment maintenance to reduce potential downtime. Folding blades often result in crisper folds of the final package when compared to compressed air folds.

Folders with multiple reverse conveyors use several variable frequency drives to reverse the conveyor drives at a specific time to complete the folds. The item traveling into a gap between two conveyors results in a cross fold when the lead-in conveyor is reversed. The complexity of these systems may present some challenges in troubleshooting the electrical system due to the increased number of drives and motors required.

Small Piece Folding Performance Metrics

All dry folding machines available on the market are directly affected by operator skill sets and the configuration of the work space. If items fed are skewed when placed by the operator on the infeed table, folds in the finished good will be skewed. Also, if the operator does not allow for proper spacing between the goods or places multiple goods on the infeed table of the machine, that can cause the folds to be incorrect and possibly do damage to the folding machine. Operator skill influences all aspects of quality.

Equipment capability or throughput capacity is a relatively simple formula. Using the folding machine measured speed at the infeed table, divide by the sum of the measured piece length, plus handling time converted into distance. The example shown below is the first step in establishing production targets for equipment operators.

Example: Folding machine infeed 150 FPM, 30” long towel and 2.5 seconds handling time.

FPM x Inch/Ft = In/min, (150 x 12) = 1,800 in/min

In/min ÷ sec/min = (1,800 ÷ 60) = 30 in/sec

Machine speed in Inch/min ÷ (handling time converted to in/sec) + part length = Pieces per minute

1,800 ÷ ((2.5 x 30) + 30) = 17.14 or 17 Pieces per minute

The example above is only a sample of single item base calculation, this should be measured against an actual operator using a sample lot of 100 parts fed.